Introducing Simple-CTM

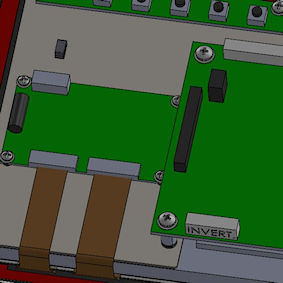

Take advantage of all the benefits of USB-C with Dawar's proprietary Simple-CTM LCD driver board! With Simple-C, one cable between your host computer and your Dawar touch-enabled monitor provides power, video, audio, touch, and USB hub functionality. Simple-C's modular design can be easily customized to work with any LCD.

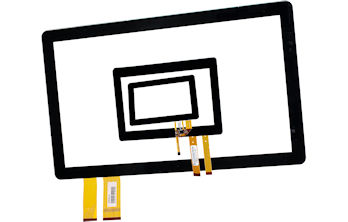

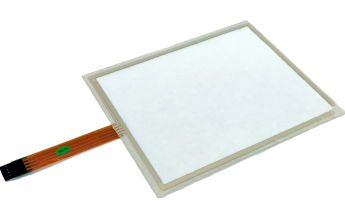

Purchase sensors & controllers

Explore sensor and controller options for Microchip and EETI Projected Capacitive products and Open Frame Products.

Research & Development: new technology advancements

With the help of our new technology advancements, you can offer your customers cutting-edge products you never thought possible!

Weathering the Storm

Having a supply chain plan that will allow you to navigate these difficult times due to the global pandemic is critical to our success and more importantly, the success of our customers.

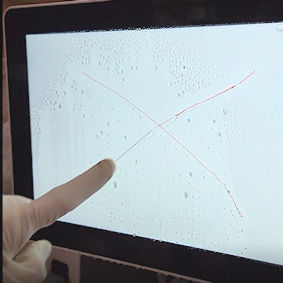

Microchip Introduces New PCAP Touch Controllers

Microchip Introduces New PCAP Touch Controllers